Providing Engineering Solutions

Engineering is the process of applying scientific principles (e.g., Newton’s three fundamental laws) in design or problem solving – and geomechanics is an engineering discipline. As geomechanical engineers or geomechanicists, we are called upon to provide engineering solutions (not just data such as results from a log or core) to problems involving rocks and soils. However, geoscience inputs and data, such as geology, seismic, petrophysics and field and lab data, underpin every geomechanical evaluation.

In order to provide engineering solutions, we may also need to consider that a rock’s mechanical behavior is coupled with the hydraulic (fluid pressure and flow) and thermal behavior… So, yes! When rock deformation is important, on top of dealing with solid and fracture mechanics, we may even need to work together with reservoir engineers.

As geomechanics engineers, we construct geomechanical models (1D or 3D descriptions of the four components of geomechanics – stress, pressure, mechanical properties and geometry) and then use analytical, empirical and/or numerical tools to analyze and predict rock mass behavior under changes in pressures, stresses etc. We compare results with field observations/monitoring to calibrate and enhance predictions in order to achieve optimal, fit-for-purpose engineering solutions to complex completion, drilling, production, reservoir and mining challenges.

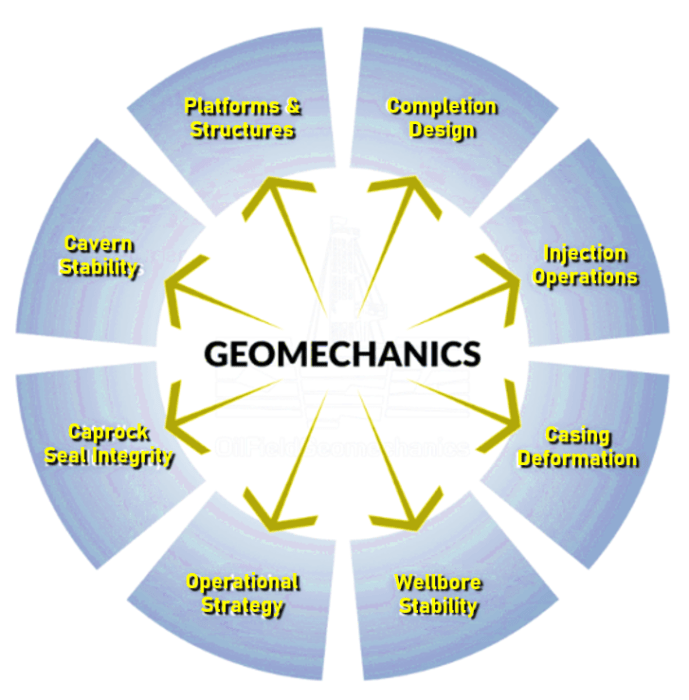

Geomechanics Problems – Solutions Are Our Expertise:

Our clients need to make engineering decisions related to how a given rock mass will behave mechanically. Example challenges we have worked on (OUR SERVICES) include:

- HYDRAULIC FRACTURING OPTIMIZATION IN UNCONVENTIONALS: Finding the optimized stimulation of shales, tight sands and carbonates (conventional reservoirs).

- WELLBORE INSTABILITY: Evaluation and prediction of stability during drilling and production (Sanding) operations.

- CAP ROCK INTEGRITY: Determination of allowable injection pressure and volumes for gas and/or carbon storage in depleted reservoirs as well as water injection operations for pressure maintenance and secondary recovery.

- FAULT STABILITY / SEISMIC ACTIVITY: Evaluation of injection (salt water disposal and hydraulic fracturing)/depletion close to faults and in high shear stress environments; evaluation of hydrocarbon leakage; evaluation of potential triggered/induced seismicity.

- CAVERN STABILITY: Geomechanical and numerical assessment of solution cavern stability and integrity – no sink hole please!

- NATURALLY FRACTURED RESERVOIRS: Geomechanical analysis of depletion and injection effects – natural fractures may close leading to irreversible permeability loss.

- CASING DEFORMATION: Evaluation of casing deformation potential in compacting and/or unconventional reservoirs – where can’t operate your wells or continue the frac jobs.

Final Considerations:

Geomechanics in the oil and gas business is, actually, a rather new field. Yes, geomechanics in the mining industry has been around for well more than 100 years, but it is relatively new in the oil and gas fields.

Before the growth in Unconventionals, the small (very small) oilfield geomechanics business was largely devoted to wellbore stability, compaction & subsidence, and reservoir compressibility (for flow simulators). With Unconventionals, there has been a significant increase in the demand for geomechanics with a primary focus on completion activities.

Note, however, that geomechanics activities span the life time of the field, cavern or asset and have relevance in many different operational applications. OFG personnel have devoted their careers to the study and evaluation of many of the geomechanics issues in the oil and gas industry as well as the mining industry.