While solution mining operations have existed for several hundred years, there has been a more recent, and growing, interest in the underground storage of CO2 (carbon capture and storage, CCS, operations) and hydrogen. These efforts put a specific focus on what drives the loss of containment, particular the loss of caprock integrity.

The construction of an underground structure, whether it be a salt cavern, a coal mine, or a subway tunnel, necessarily involves the geomechanical evaluation of the stability of the underground structure in order to prevent collapse of the structure and/or prevent leakage of fluids from or into the structure.

While simply analytical models have been employed to assess the stability of simple subsurface geometries (like a circular tunnel), most underground structures are highly complex and required detailed, 3D geomechanical modeling (and the associated data requirements of said model). Particularly for high risk evaluations involving limited quality data, parametric modeling must be performed in order to assess the impact of the uncertainty in the input data.

OFG works with out clients to develop both the necessary geomechanics data (and quantify its uncertainty) and perform the appropriate engineering to assess cavern stability and support long-term underground storage operations.

Cavern Stability in Solution Mining

Geomechanical modeling of solution mining operations, in order to assess the stability of the created cavern as well as potential surface subsidence effects, works hand-in-glove with cavern operations. That is, it is the cavern operational decisions (e.g., direct vs. reverse circulation) that determine cavern shape, which has a direct impact on cavern stability.

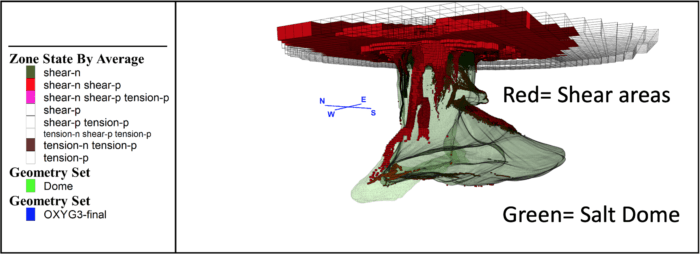

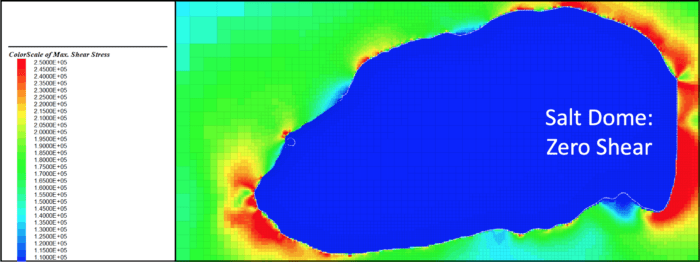

A proper geomechanical assessment of a solution mining cavern, particularly one close to the edge of a salt dome, starts with geomechanical simulations of the stresses surrounding the salt dome. A basic input for this initial analysis is the dome shape itself, which is often highly uncertain. Once the influence of the dome geometry (along with external formation properties, stresses and pressures) has been evaluated, simulations of various cavern geometries can be evaluated as a function of operational plans.