Whether for petroleum, mining, tunneling or other applications, GEOMECHANICS is the engineering evaluation of the behavioral interplay between 1) stress and stress changes; 2) pressure and pressure changes; 3) mechanical properties (both deformational and strength); and 4) and geometry in rock and soil.

1D Geomechanical

Models

3D Geomechanical

Models

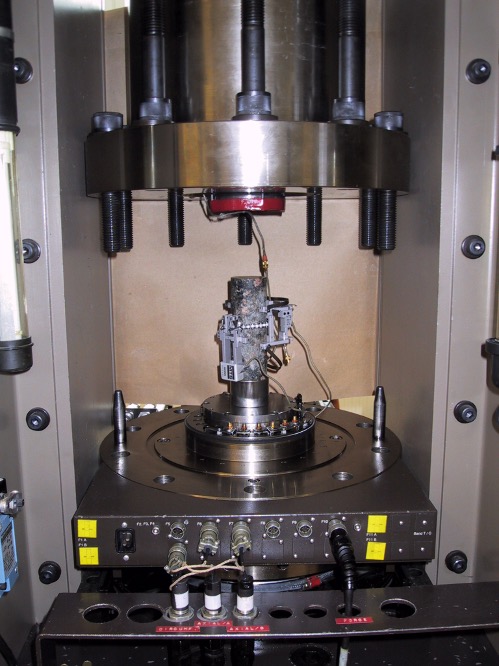

Laboratory

Testing

The GEOMECHANICAL MODEL is the starting point of any geomechanical analysis. It describes four components:

- Rock mechanical properties of deformation and failure for each lithology and/or spatial area;

- Stresses (the complete tensor – principal components Sv, SHmax, Shmin, magnitude and orientation – accounting for tectonics and structural position);

- Pore pressures (including fluid type); and

- Geometry (well trajectory, reservoir limits, fault geometry, cavern geometry, etc.)

The description and distribution of these four components form the basis of the geomechanical model (or Mechanical Earth Model, in some references). It may be a 1D geomechanical model (based upon a single well data set) or a 3D model, considering layers, faults and rock masses in the reservoir and over, under, and side-burden.

We build and calibrate geomechanical models for our projects, following a state-of-the-practice workflow and utilizing state-of-the-art tools and programs, with information gathered from:

- Well Data: Log data (e.g., GR, sonic, density, resistivity, image, and caliper); Injectivity test data (e.g., DFITS, mini-fracs, LOTS, Step rate tests, and well testing); rock mechanics laboratory data; pore pressure data (e.g., logs, RFTs, and MDTs); and drilling parameters and cavings information.

- Field Data: Geometry of layers and faults (e.g., seismic, elastic inversion, geological, structural model, and static model); elastic properties and strength (e.g., seismic inversion, logs, and correlations); and pore pressure (e.g., seismic and basin modeling).

It is also important to note that the geomechanics model is not simply a database of geomechanics data. Particularly in its 3D mechanistic form, a geomechanics model is used to solve for, amongst others, the equilibrium equations and Hooke’s Law in order to evaluate stress changes and deformations due to, for example:

- reservoir depletion

- water injection

- hydraulic fracturing

- drilling a wellbore

- solution mining a salt cavern

- carbon storage and others.

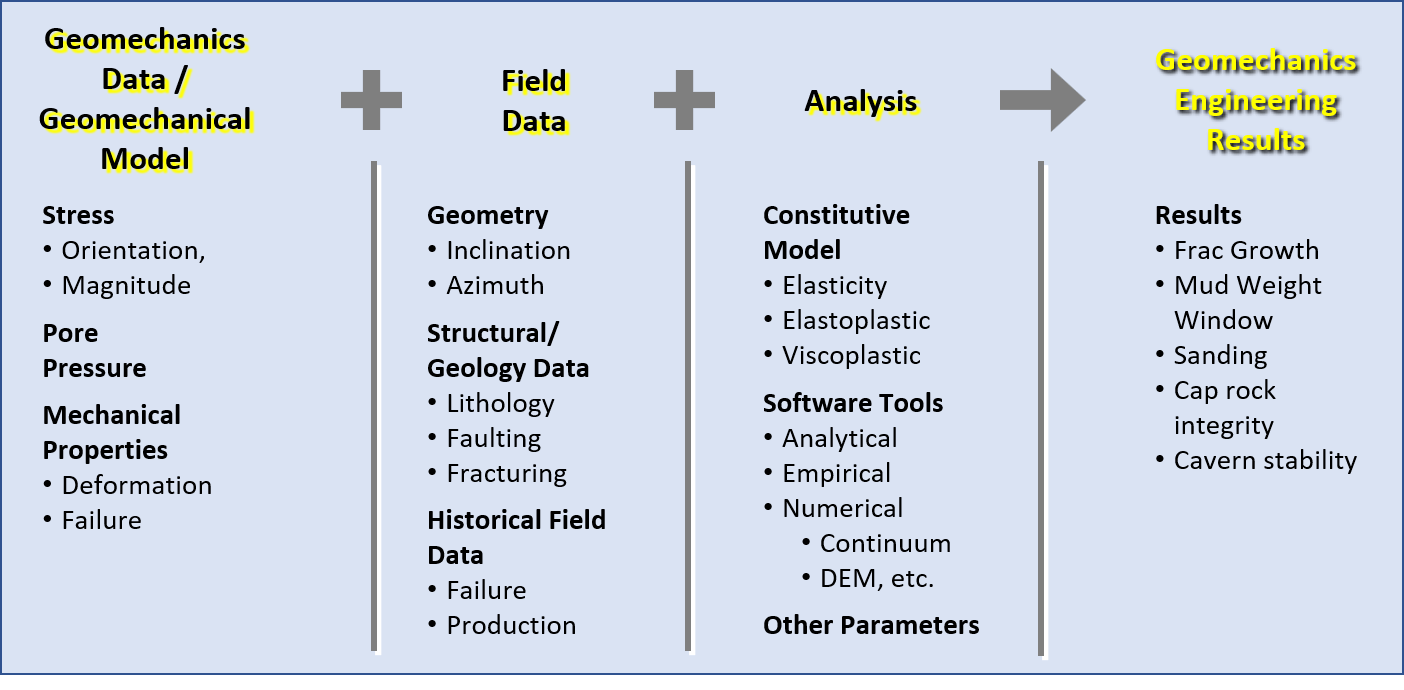

Basic Geomechanics WorkFlow:

In order to tackle a geomechanics problem, we start by building a geomechanical model (determination of stresses, mechanical properties and pore pressure along or within a geometry) encompassing the problem domain. Then field data is considered, including geology and subsurface structures, and the historical data representing rock failure and/or well/field behavior and production is evaluated in order to provide calibration of the geomechanics model.

The analysis of the problem is carried out with fit-for-purpose tools (analytical, empirical or numerical) considering rock stress/strain behavior (the constitutive model) and a failure criteria. Perturbation of stresses, displacements and/or pore pressure are imposed to let the model predict the outcome of a particular problem – hydraulic fracture growth, safe mud weight window, sanding occurrence, stability of cap rock, cavern stability, etc. Monitoring in the field is then collected and used as a feedback for model validation and prediction under changing scenarios.

Log Geomechanics vs. Lab (Core) Geomechanics

As listed earlier, geomechanics data comes from many different sources – and because this data tends to be so sparse and the domain we are interested in is so under sampled – all this data needs to be employed. Nonetheless, all data is not created equal – nor do they have the same value (i.e., accuracy and/or representativeness). This holds true for the on-going debate between log-based and lab-based (core-based) geomechanics.

What is meant by log vs. lab geomechanics? Log-based geomechanics is, as the name suggests, derived from wireline log data run across some interval of a wellbore – the principal logs being sonic, density and GR. Lab or core-based geomechanics is, again as the name suggests, derived from the laboratory testing of rock core obtained during the drilling of a wellbore. Fundamentally, log-based geomechanics and lab-based geomechanics are, essentially, opposites in that what one does well the other does poorly:

| Log-Based | Lab/Core-Based | |

|---|---|---|

| Accuracy | 3 | 1 |

| Coverage | 1 | 3 |

| Cost | 2 | 3 |

| Timeliness | 1 | 3 |

Ranking: 1 (best) – 3 (worst)

The chief benefit of log-based geomechanics is that the data comes from logs, which are routinely and commonly run in almost all wellbores. This means that the logs can provide coverage over an extensive interval of the formations (i.e., as much as specified to the logging company) and be available at a somewhat reasonable cost and in a reasonable timeframe. However, the likely more important part is that the geomechanical parameters derived from logs vary from being inaccurate (in the case, for example, of dynamic elastic parameters) to highly inaccurate (in the case, for example, of strength parameters like UCS and friction angle) with log-based stress predictions somewhere in between.

The chief limitations of lab-based (core-based) geomechanics are that there is typically limited core (so formation coverage tends to be poor), coring is very expensive, and the results can take months to deliver. However, when the core is taken and handled properly and the testing is conducted properly, the laboratory results for deformational parameters (like Young’s modulus and Poisson’s ratio) and failure parameters (UCS and friction angle) can be very accurate.

A proper geomechanics data acquisition program, then, is not a choice between log-based or lab-based geomechanics but rather a choice of how best to combine the two to achieve the best data within the budget and time constraints provided. This can be achieved by incorporating geomechanics engineering expertise with proper project scoping and management buy-in.