With the growth of interest in Carbon Storage (CCS) as well as underground storage of hydrocarbons, the geomechanics of Caprock Integrity has become of major interest. Nonetheless, the geomechanical integrity of the bounding layers around a given reservoir has been a well-known concern for, for example, waterflood operations for decades.

The “caprock” is considered to be the bounding, low permeability formation immediately above the injection horizon (or the overlying bounding layer above a salt formation). Sometimes, the injection horizon is at virgin pressure, but, in many cases, the injection horizon is at a depleted pressure (due to production of oil & gas or water). A Caprock Integrity Assessment is used to evaluate the central geomechanical issue for storage and sequestration operations – will the low permeability of the caprock, during pressurization or repressurization of the injection zone, be maintained in order to trap the injected fluid (CO2, hydrocarbons, or water for waterflood operations) in the injection zone.

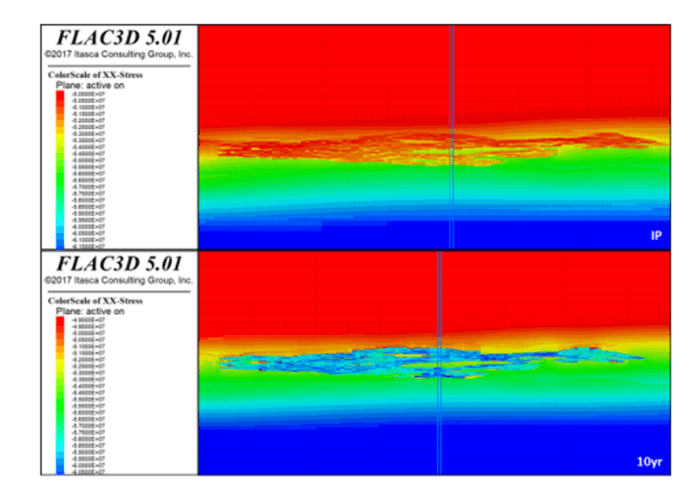

A geomechanical analysis of caprock integrity begins with a geomechanical assessment of the injection zone and caprock itself (stresses, pressures and mechanical properties), with a particular focus on structural features like through-going faults. Of particular concern is that faults may be reactivated and become permeable during depletion/repressurization operations.

At OFG, we use the calibrated 3D geomechanical model, once the base case conditions (structure, stresses, pressures, and mechanical properties) have been established, to evaluate various injection and depletion scenarios including:

- • Reservoir depletion scenarios;

- • Water injection for pressure maintenance into a virgin pressure or depleted pressure reservoir;

- • CCS operations; or

- • Injection pressure and volumes for gas storage into a depleted reservoir.

From a geomechanical perspective, changes of reservoir pressure induce changes in the principal stresses, particular Shmin (the minimum horizontal stress or sometimes considered the Fracture Gradient), and therefore the safe injection pressure for cap rock integrity may change. Because in-situ stresses will change with formation pressure changes, the injection pressures that are sustainable to perform waterflooding operations prior to reservoir depletion, for example, may no longer be safe if waterflooding (repressurization operations) is implemented after pressure depletion has occurred.

OFG can develop a complete geomechanics evaluation plan and assessment, including data collection, 3D geomechanical model parametric analyses, and long-term monitoring, to help our clients insure safe, long-term injection (reinjection), repressurization and storage/sequestration operations.