In order to develop nano- and microdarcy permeability Unconventional reservoirs, multistage hydraulic fracturing (HF) is needed in order to make economic wells. At OFG, we consider that at least three main rock fabric scenarios may be present in the unconventional plays (both regionally and, often, within a single wellbore):

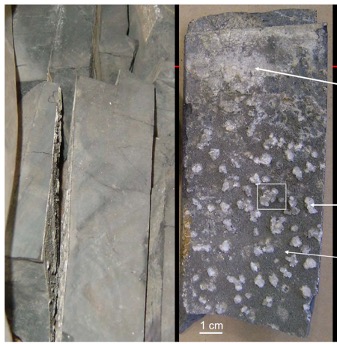

- – a highly fractured rock mass (e.g., a fault zone) where HFs cannot be created (left, below);

- – formations with cemented or nonexistent discontinuities where traditional HF design – where rock fabric is ignored – can be successfully applied (right); or

- – formations with weakly cemented or open/partially open natural fractures or weakness planes in which the stimulation objective is to stimulate these weak planes (center).

OFG starts a hydraulic fracturing project by first understanding (via resource characterization) the particular scenario for hydraulic fracturing design – because different design strategies are needed for each case.

Geomechanical Rock Fabric Scenarios for Hydraulic Fracturing in Unconventionals

Critically, these rock fabric scenarios:

- – Do NOT stimulate the same;

- – Do NOT exhibit the same

- microseismic behavior; and

- – MAY NOT produce the same….

No Two Shale Plays Are Alike

After several decades of sometimes painful and expensive efforts, the industry now largely understands that no two Unconventional plays are the same. What works successfully in one play often does not translate to another play. This is, in large measure, due to differences in:

- – geochemistry;

- – shale mechanical and petrophysical properties;

- – fluid pressures;

- – stress field; and

- – rock fabric characteristics (natural fractures and bedding planes)

What OFG Believes Are The Critical Issues With Hydraulic Fracturing in Unconventionals

OFG has worked with many clients and written numerous papers on the geomechanics of hydraulic fracturing in Unconventionals. We have also taught dozens of courses, with more than a thousand total students, on the subject. You will also find, in the download section, our paper on the comparison of what we call the conventional hydraulic fracturing paradigm to the Unconventional hydraulic fracturing paradigm. In short, we think the key difference is rock fabric (rock fabric, rock fabric, rock fabric!), but with, more detail, we think the keys are:

- Presence of the resource (TOC, maturity);

- Presence of natural fractures and/or weak planes (free surfaces to be converted to flow area) and their connectivity and hydro-mechanical properties;

- Fluid pressure and fluid type – high pressures favor the stimulation of natural fractures, as the effective stresses are low and less shear is needed for stimulation, and can pressure be increased in offset wells during a stimulation;

- Influence of stresses and mechanical properties on HF geometry and

SRVdrainage volume – some conditions are more favorable than others; and - Influence of operational parameters and HF design on HF geometry and

SRVdrainage volume.

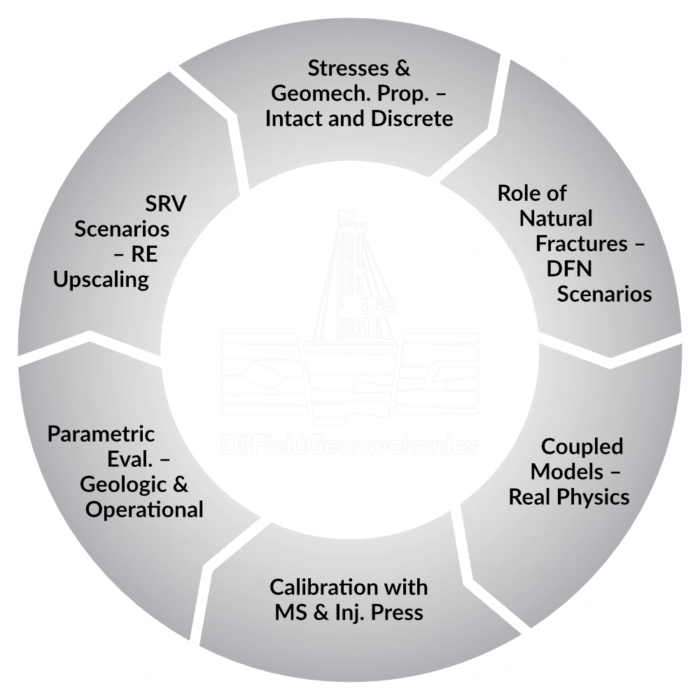

Each of these issues, other than the presence of the resource, are controlled by the geomechanical behavior of the rock mass (stresses/strains and failure) coupled with fluid flow and pressure changes. OFG uses models that incorporate the right physics for coupled geomechanics and fluid flow, including the natural fractures and weakness planes, in order to represent rock mass failure, stress capture effects, changes in the shape of HFs with multiple stages, changes in ISIP (Stress Shadows) and its effect on the natural fractures, microseismic behavior, casing deformations, etc. The field data (microseismicity, injection pressures, PLTs, tracers and ultimately production) together with the models help us understand and quantify the effects of geomechanical, reservoir, geological and operational parameters on stimulation efficiency (increased SRV drainage volume) and optimization strategies.

A Note on Hydraulic Fracturing Models

If you are like us, it might be nice to own, say, a fancy race car like the original 1960s Ford GT40. You could tool around on Sundays and show up all those street racers. But it wouldn’t be practical for getting the kids to school or picking up lumber from the home store. Frac models are like this. The choice of frac model – like our car choice – needs to be fit-for-purpose.

There are a number of go-to commercial frac models that have been around for decades. StimPlan from NSI and Gohfer from Barree come to mind. On the other hand, there are a number, now, of specialty hydraulic fracture models (more akin to geomechanics models that do hydraulic fracturing simulations) that have been developed to handle the geomechanics of hydraulic fracturing in the presence of rock fabric. GEOS from Lawrence Livermore National Labs or XSite from Itasca come to mind.

Which of these is “best”? In the absence of rock fabric, why use a HF simulator that needs a super computer to run on (just like trying to use our Ford GT40 to get the kids to school – it can be done, but why would you). However, where rock fabric dominates (production, hydraulic fracture propagation, frac hits, casing deformations or the like), you need a tool to perform the correct engineering.

OFG Hydraulic Fracturing in Unconventionals Services

Please visit our Multistage Hydraulic Fracturing Optimization page to see our consulting services for hydraulic fracturing in Unconventionals.