Historically, wellbore stability evaluations have been the main application of geomechanics in the oil and gas industry. Wellbore stability evaluations are conducted in order to address the problems of stuck pipe, kicks, lost circulation, sloughing shales, and inflows. Over the recent decades, numerous publication have suggested that wellbore instability has resulted in some 40% of total non-productive time (NPT) during drilling operations, at a cost to the industry of up to $8 billion per year. These numbers have come down, particularly in Unconventionals; nonetheless, NPT is still a key driver of the capital cost of many wellbores, both onshore and off.

A wellbore stability evaluation starts with the development of a geomechanical earth model (i.e., the distribution of stresses, pore pressure and mechanical properties) along a well trajectory, typically this is a 1D geomechanical model. Each of the three geomechanics inputs – as well as well trajectory (geometry) – is critical to a successful stability analysis. Especially note that, unlike reservoir geomechanics that tends to be isolated to the reservoir formation itself, a quality wellbore stability evaluation is dependent upon solid geomechanics data in all the formations the well will pass through.

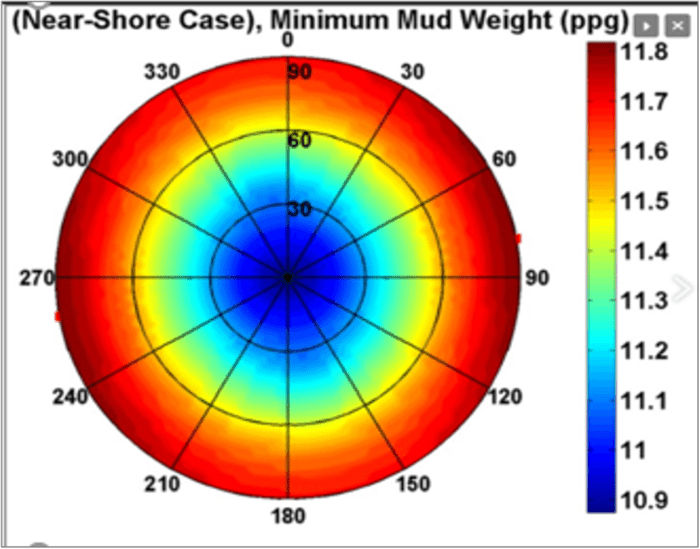

With the proper geomechanics data, and using geomechanical tools (analytical or numerical) to evaluate stresses induced by the borehole and comparing with a failure criteria, the Safe Mudweight Window can be developed.

Critical Factors in Wellbore Stability Analyses

There are a number of critical inputs for a successful stability analysis. OFG will consider the following during a comprehensive wellbore stability evaluation:

- • Well trajectory (inclination and azimuth) by formation;

- • Consideration of permeable vs. impermeable formations (and consideration of the type of drilling mud);

- • Errors in pore pressure magnitudes (and location of the onset of overpressuring, if present);

- • Errors in stress (all three principal stresses) and particularly the influence of SHmax;

- • Errors in rock strength (both UCS and friction angle);

- • Influences of the chosen Failure Model on results;

- • Effects of formation strength anisotropy (e.g., bedding planes and natural fractures);

- • Thermal effects; and

- • Mud salinity and chemistry effects (particularly in shales).

Real Time Wellbore Stability

One step beyond real time pore pressure prediction is the use of wellbore failure indicators to update the wellbore stability analysis in real time. The future of cavings volume and morphology automatic recognition is coming soon. link to Drilldocs page.

Managed Pressure Drilling and Others

Managed pressure drilling (MPD) and other drilling techniques are in increasingly common usage in order to reduce well costs. The success of these techniques still relies on a quality evaluation of wellbore stability!